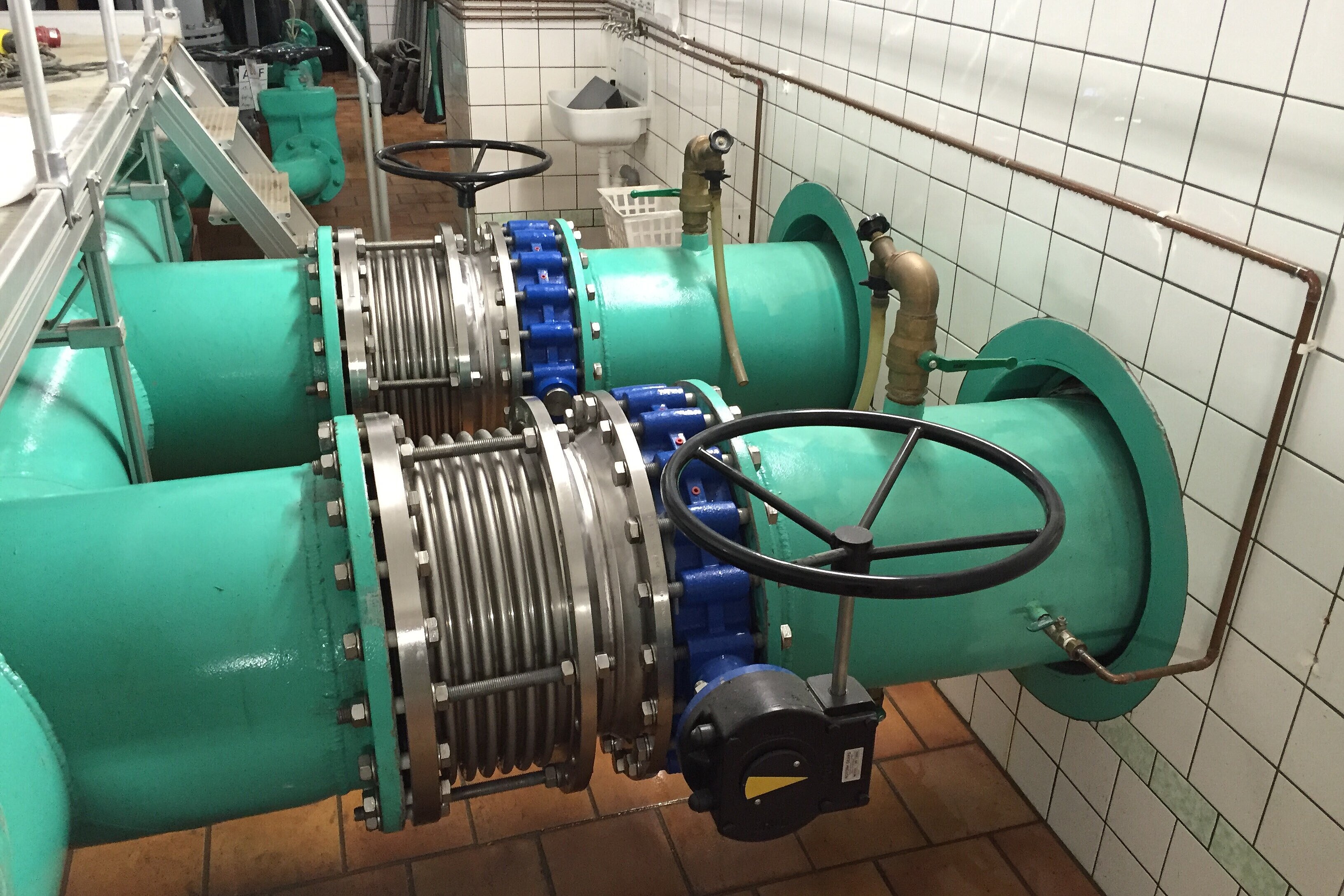

Lateral expansion joints in a pipe system

Often a compensating element in the form of an expansion joint is required if it is not possible to compensate the expansion in the piping systems by simple design measures.

Depending on the type of movement, a distinction is made between axial, lateral and angular compensators.

Depending on the type of movement, a distinction is made between axial, lateral and angular expansion joints. The fixed points in the piping system are loaded with the following forces:

- Pipe friction force

- Spring stiffness of the metal bellows (axial, lateral and angular)

- pressure reaction force of the metal bellows (F = p x A)

In a properly designed pipeline, only one axial expansion joint between 2 fixed points must be provided. The spring rate of the metal bellows cannot withstand the pressure reaction force, caused by the internal pressure. If the fixed point is not dimensioned correctly, then the piping system is pushed apart.

See also Flexomat's installation instructions for expansion joints.

compressor test stand

pipe system in a chemical plant

Universal expansion joints in a pipe system

exhaust pipe

Universal expansion joint in a exhaust pipe

bellows dismantling joints

Axial expansion joint for an easy mounting and demounting of valves or similar devices

Lateral expansion joints

absorb movements vertical to the bracing plane

Angular expansion joints

absorb axial offset through angular movement

Axial expansion joints

compensate assembly tolerances and thermal longitudinal expansion in the direction of the tube axis.

Universal expansion joints

absorb simultaneous axial, lateral and angular movements

Special designs

are used in particularly demanding applications or customer requests.